Conica has been developing and installing running tracks for over 40 years. The company is one of the market leaders and innovation drivers. The tracks are cast, not rolled out. Each year, Conica installs approximately 200 running tracks worldwide. Cast tracks offer several advantages over rolled ones.

What makes Conica special? Cast instead of rolled out running tracks!

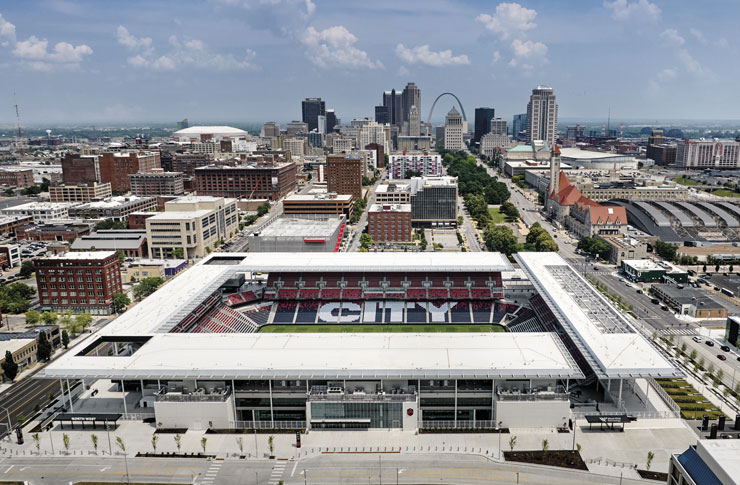

The Stade Louis II is the centre of competitive sports in the Principality of Monaco (Photo Copyrights: Conica AG).

Manufacturing and installation

The Conica system components are delivered in liquid form and processed and cast on site by trained forces. Compared to alternative surfacing materials, the advantages are high elasticity and protective function, optimum mechanical and chemical resistance, long service life, and easier maintenance thanks to jointless surfaces.

Another advantage is that unevenness of the underground can be evened out. This compensation is more difficult with roll material, because unevenness must be corrected in advance. Subsequent correction in the further course of installation is no longer possible.

There is also a difficulty in curves when installing roll goods. When the material is bonded to the substrate, it is stretched in the outer area. This means that the rolled material does not have absolutely equal characteristics in the curves.

The joints between individual sheets are a general problem with rolled tracks. Although they are closed, they prove to be a disadvantage in the course of service life, as they can open up due to weather conditions. The advantage of cast Conica tracks, on the other hand, is that there are no joints at all.

Cast tracks offer several advantages over rolled one. The system components are delivered in liquid form and processed and cast on site by trained forces.

Sports characteristics and service life of the system

Another benefit of cast Conica tracks is that the material is durable and retains most of its characteristics. Tracks made of rolled material, on the other hand, harden after only a few months and prove to be a burden for the athletes. A major disadvantage of very hard running tracks is also that if athletes get their spikes into the joints, material can break out, reducing the quality of the track.

Costs and refurbishing options

Cast running tracks are significantly less expensive than rolled products at the premium end of the market. Cast tracks also offer advantages when it comes to refurbishment. Everything from a simple facelift to retopping the base and surface layers to complete renewal is feasible. Rolled tracks, on the contrary, can only be completely replaced.

Stade Louis II, Monaco.

(News by Conica AG).