The Angelo Scalzone has been renovated with a synthetic grass surface for the football field and the redesign of the athletics track.

Casal di Principe (Caserta): upgrading of the municipal sports facility

The project is part of the more general upgrading of sports facilities in the municipality of Casal di Principe, and was necessary to support, encourage and improve sports activities.

The sports facility named “A. Scalzone” includes: a football pitch, already in natural grass, a covered and an uncovered spectator stand, a changing room block and a service block.

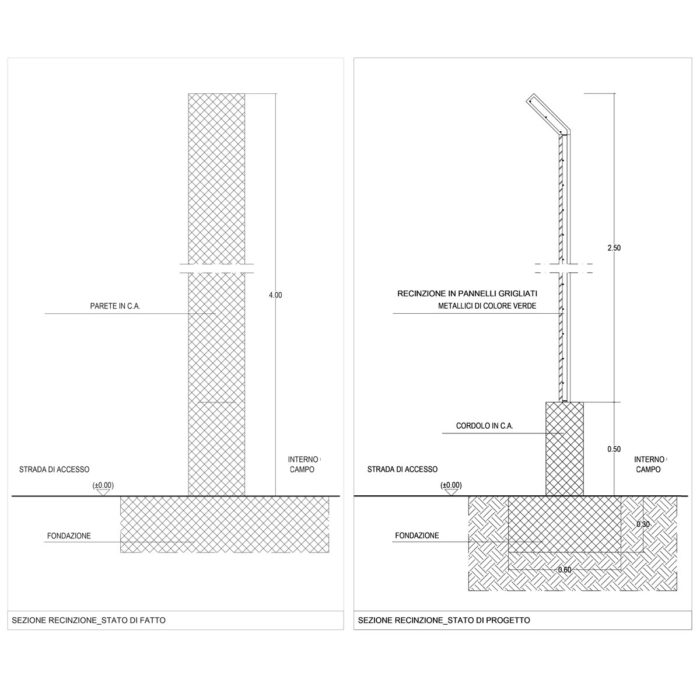

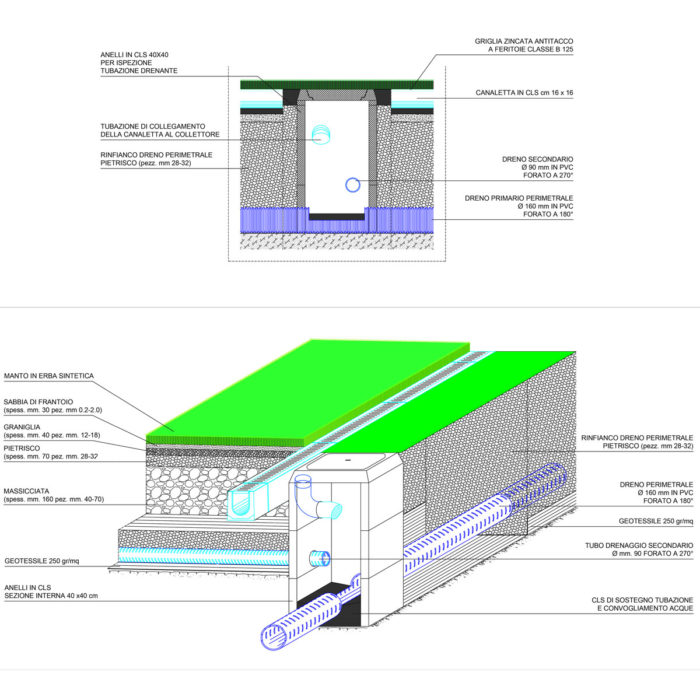

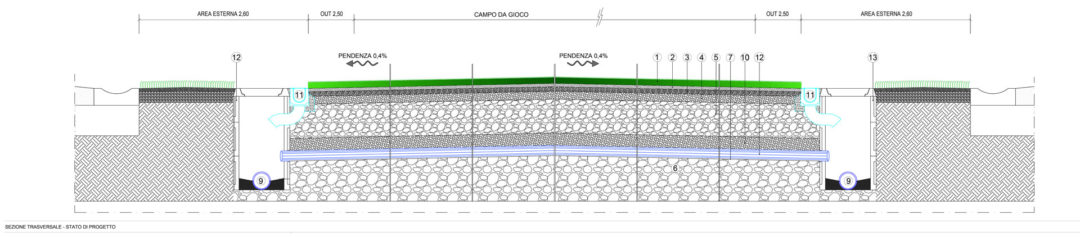

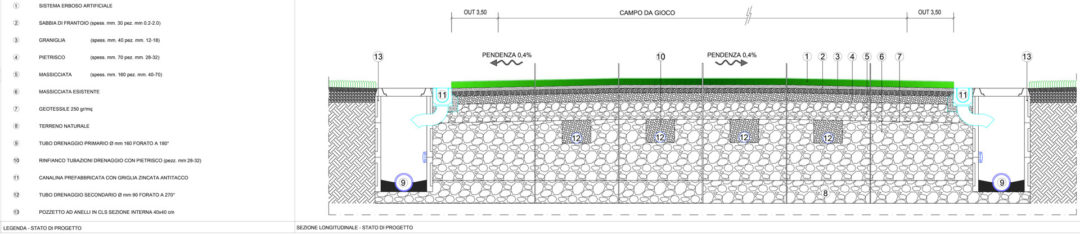

The work carried out includes: the transformation of the surface from natural grass to artificial grass; the partial replacement of the fence; the construction of a new drainage system; the construction of a new irrigation system; the replacement of the athletics track.

There are no plans for work on the grandstand and changing rooms.

The artificial turf is made of 52 mm high, 400 micron thick polyethylene yarn combined with a prefabricated elastic underlay. The double shade of green used for the yarn gives the turf a natural appearance while preserving the aesthetic and landscaping aspect of the project. The special diamond shape ensures an immediate return of the fibres to a vertical position after walking, guaranteeing a perfect bounce and sliding of the ball and a natural twist and grip of the foot.

The performance infill is made of elastomeric rubber granules, obtained by grinding selected rubber free of dust or foreign parts, covered and encapsulated with a film of virgin polyurethane resin, painted and finished with ecological and non-toxic pigments to obtain an odourless and highly abrasion-resistant product.

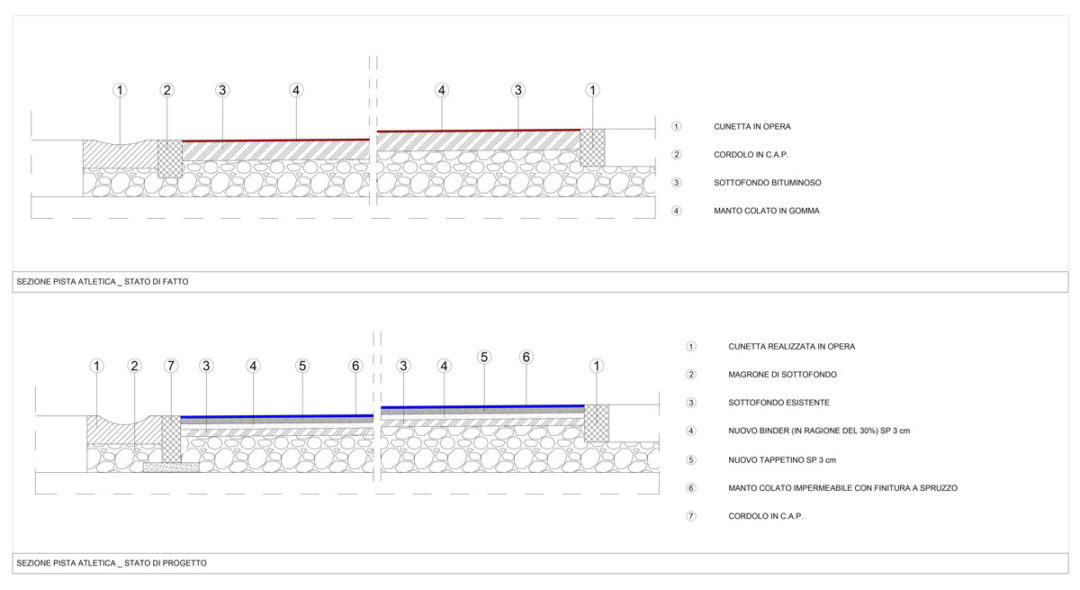

The 6-lane athletics track will be used as an exercise facility. The synthetic surface has been rebuilt, as the state of deterioration of the existing surface made retopping alone impractical.

The sports surface is a poured synthetic turf, waterproof and two-coloured in thickness, with a sprayed finish. The base layer, 10.50 mm thick, is cold-formed by pouring a mixture of black SBR rubber granules and a single-component polyurethane polymer as binder; the surface wearing layer, 2.50 mm thick, is made by spraying a mixture of coloured polyurethane resin and coloured rubber granules.