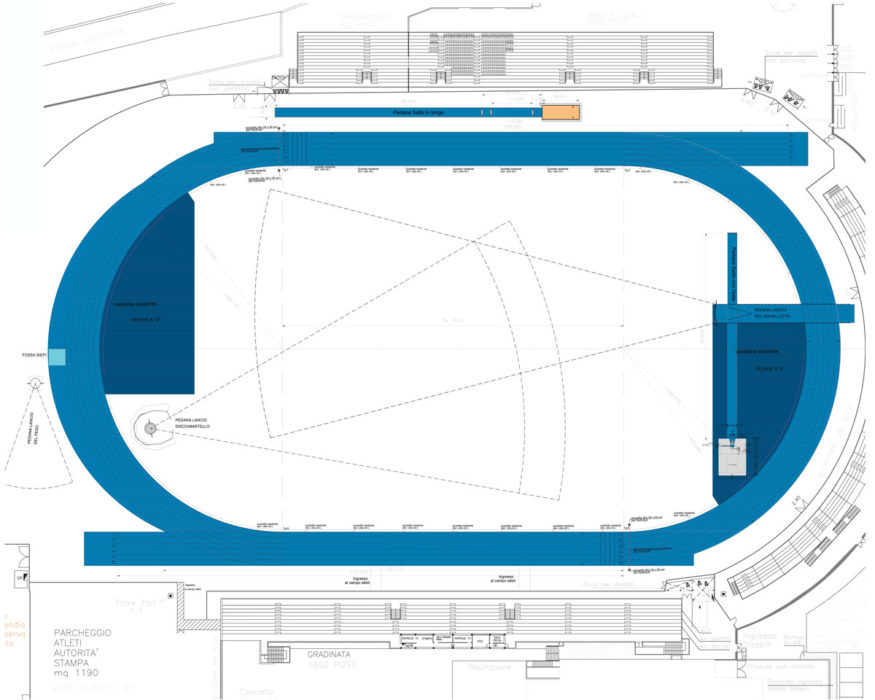

The athletics track inside the Blasone stadium in Foligno (Perugia), had a homologation dating back to 1990, therefore no longer valid, and in fact no longer responding to the technical and performance characteristics required for sports activities.The planimetric characteristics of the track and the platforms make it possible to request homologation in the class identified…

Foligno: renovation of the athletics track at the Enzo Blasone Stadium

The athletics track inside the Blasone stadium in Foligno (Perugia), had a homologation dating back to 1990, therefore no longer valid, and in fact no longer responding to the technical and performance characteristics required for sports activities.

The planimetric characteristics of the track and the platforms make it possible to request homologation in the class identified for complete outdoor 400.00 m. 6-lane ring facilities.

In order to lay the new flooring, it was necessary to smooth the existing surface by at least 2/3 mm, and then level it with a two-component polyurethane adhesive spread over the entire surface to be treated to obtain a correct laying surface. The athletics surface was then laid in compliance with FIDAL regulations and IAAF approved, using a first support layer of prefabricated sheet consisting of fibres and granules of selected SBR rubber with controlled dimensions, mixed and joined with a single-component polyurethane binder.

The prefabricated rubber layer was produced in rolls with constant and uniform performance, with a thickness of 10 mm. The roll was bonded to the previously treated substrate using a specially formulated two-component polyurethane adhesive.

The final surface layer with a nominal thickness of 3 mm was carried out by trowelling a first layer of the prefabricated sbr mat with a two-component polyurethane skim coat and the subsequent application of a second layer with a continuous, nail-resistant coating, applied in the liquid state, consisting of several layers of self-levelling polyurethane. The surface finish was carried out by manual seeding of blue EPDM rubber granules in different shades with a controlled diameter of 1.0 – 3.5 mm.

Testing is scheduled for September.